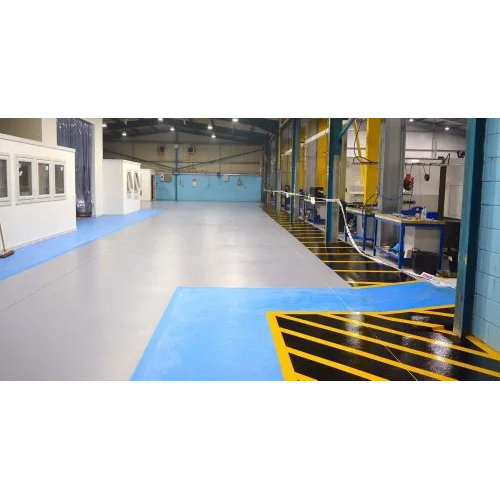

Chemical Resistant Industrial Epoxy Flooring Service

40 आईएनआर/Square Foot

उत्पाद विवरण:

X

मूल्य और मात्रा

- 1000

व्यापार सूचना

- प्रति महीने

- दिन

उत्पाद वर्णन

Take advantage of our popular Chemical Resistant Industrial Epoxy Flooring Service at a reduced price for a limited time. Offering blue-ribbon performance, this splendid epoxy flooring solution boasts compressive strength of 70 N/mm2, adhesion strength >1.5 N/mm2, and customizable thickness (1-5 mm). Designed for demanding industrial environments, it features gorgeous, seamless glossy finishes with robust chemical resistance, minimal water absorption (<0.1%), and temperature durability up to 70C. Slip resistance and color options are tailored to your requirements. Enjoy comprehensive service, rapid curing, and supply across India, backed by reliable manufacturers, suppliers, and service providers.

Versatile Surface Application and Industrial Usage

Our Chemical Resistant Industrial Epoxy Flooring Service is expertly crafted for application on a range of industrial surfaces, guaranteeing utmost durability and protection. This solution is ideal for facilities where enhanced chemical resistance and heavy-duty performance are paramount, such as manufacturing units, laboratories, and warehouses. The specific usage focuses on indoor, high-traffic zones, supporting functions that demand a safe, seamless finish. Choose this solution to grant your industrial surfaces a blue-ribbon upgrade.

Reliable Supply, Packaging, and Valuation for Domestic and Export Markets

We supply Chemical Resistant Industrial Epoxy Flooring सेवाएं across all major domestic markets in India, especially Pune, Mumbai, and Bangalore, with export capabilities to meet global demands. Every project receives clear valuation and efficient packaging of labour and materials for safe handover. Our strict adherence to quality ensures that flooring is delivered ready for application, allowing businesses to maintain timelines and maximize operational uptime with minimal disruption.

Versatile Surface Application and Industrial Usage

Our Chemical Resistant Industrial Epoxy Flooring Service is expertly crafted for application on a range of industrial surfaces, guaranteeing utmost durability and protection. This solution is ideal for facilities where enhanced chemical resistance and heavy-duty performance are paramount, such as manufacturing units, laboratories, and warehouses. The specific usage focuses on indoor, high-traffic zones, supporting functions that demand a safe, seamless finish. Choose this solution to grant your industrial surfaces a blue-ribbon upgrade.

Reliable Supply, Packaging, and Valuation for Domestic and Export Markets

We supply Chemical Resistant Industrial Epoxy Flooring सेवाएं across all major domestic markets in India, especially Pune, Mumbai, and Bangalore, with export capabilities to meet global demands. Every project receives clear valuation and efficient packaging of labour and materials for safe handover. Our strict adherence to quality ensures that flooring is delivered ready for application, allowing businesses to maintain timelines and maximize operational uptime with minimal disruption.

| Provide सेवाएं In | Industrial |

| Flooring Type | Epoxy |

| Features | Chemical Resistant |

| Usage/Application | Indoor |

| Location Served | Pune, Mumbai, Bangalore |

| Minimum Area (in sq. ft.) | 1000 sq ft |

| Service Provided | Labour & Material |

FAQ's of Chemical Resistant Industrial Epoxy Flooring Service:

Q: How does the chemical resistant epoxy flooring process work?

A: Our flooring process begins with preparing the surface through mechanical grinding or shot blasting, followed by the application of the epoxy system using a roller, brush, or spray. Initial curing occurs in 24 hours, with a complete cure achieved in 7 days, ensuring robust adhesion and long-lasting performance.Q: What are the main advantages of using chemical resistant epoxy flooring in industrial applications?

A: Epoxy flooring offers excellent durability, seamless gloss finish, low water absorption, and exceptional resistance to chemicals and temperatures up to 70C. These benefits make it suitable for heavy-duty and high-traffic industrial environments, reducing maintenance and increasing safety.Q: When is the ideal time to apply this flooring service?

A: The flooring should be applied on clean, prepared surfaces in areas where operations can be paused for 2-5 days, depending on the area size, to allow for proper installation and curing.Q: Where is this epoxy flooring service available?

A: This service is available all over India, with a focus on major industrial cities including Pune, Mumbai, and Bangalore. We also support export markets, ensuring wider accessibility.Q: What customizable options are available for this flooring service?

A: Customers can customize the flooring's color, slip resistance, and thickness (from 1 mm to 5 mm) based on the specific requirements of their industrial environments.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email