Coal Tar Epoxy Coating Services For Waterproofing

Product Details:

X

Coal Tar Epoxy Coating Services For Waterproofing Price And Quantity

- 100 Square Foot

Coal Tar Epoxy Coating Services For Waterproofing Trade Information

- Telegraphic Transfer (T/T)

- 5000 Square Foot Per Month

- 7 Days

Product Description

Ensure lasting waterproof protection with our Coal Tar Epoxy Coating Services. Crafted specifically for waterproofing applications, our coal tar epoxy forms a robust barrier against moisture, chemicals, and corrosion. Ideal for surfaces exposed to harsh environments, such as bridges, pipelines, and marine structures, our coating provides exceptional durability and resistance. Trust our experienced team to apply this high-performance solution meticulously, safeguarding your assets and infrastructure from water damage. Invest in reliable waterproofing with our Coal Tar Epoxy Coating Services for lasting peace of mind.

Advanced Waterproofing for Multiple Surfaces

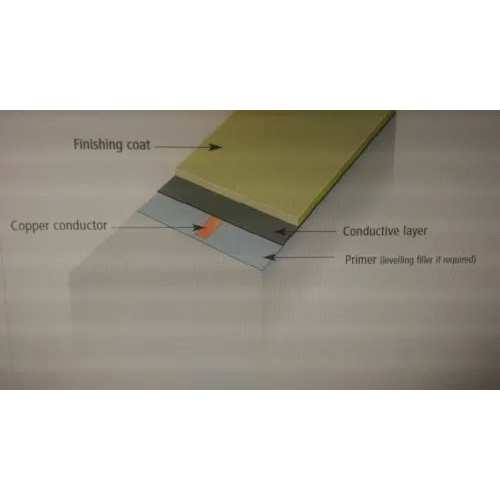

Our coal tar epoxy coating is specially formulated for superior waterproofing on concrete, steel, roofs, basements, and tanks. Its high adhesion ensures a long-lasting barrier, making it ideal for areas exposed to harsh elements or chemicals. With a seamless finish and flexibility in glossiness and thickness, we tailor every application to your unique project specifications.

Service Delivery with Precision and Care

Delivered entirely offline and on-site, our team manages the intricacies of surface preparation, applying coal tar epoxy coatings using mechanical cleaning or blasting to maximize adhesion. Careful attention is given to curing and weather resistance, ensuring lasting protection and optimal performance regardless of environment.

FAQ's of Coal Tar Epoxy Coating Services For Waterproofing:

Q: How is coal tar epoxy coating applied during the waterproofing service?

A: The coating is applied by skilled technicians using brushes, rollers, or spray equipment. Surface preparation includes mechanical cleaning or blasting, which helps maximize adhesion. Application thickness, finish type, and curing requirements are tailored to the surface and project needs.Q: What surfaces are suitable for coal tar epoxy waterproofing?

A: Coal tar epoxy coating is suitable for concrete, steel structures, roofs, basements, and tanks. Its high chemical and weather resistance make it ideal for industrial and commercial sites seeking durable, seamless waterproofing solutions.Q: When can the coated surface be put to use after application?

A: After the coal tar epoxy is applied, a minimum curing time of 24 hours is required. However, for full performance, curing times may vary depending on the environment and project scope. It's recommended to allow proper curing before subjecting the surface to water or load.Q: Where are your services available, and who can avail them?

A: Our coal tar epoxy coating services are provided on-site across India. We cater to industries, commercial spaces, and property owners who require professional waterproofing for concrete, steel, roofs, basements, or tanks.Q: What is the typical process involved in coal tar epoxy coating for waterproofing?

A: The process begins with surface preparation, including mechanical cleaning or blasting to remove contaminants. Next, the coating is applied as per the specified thickness using brush, roller, or spray. The applied surface is then left to cure for at least 24 hours to achieve optimal adhesion and durability.Q: How long does coal tar epoxy coating last, and what are its primary benefits?

A: Depending on exposure conditions, the coating typically lasts between 5 to 10 years. Key benefits include excellent chemical resistance, high waterproofing efficiency, durability, low VOC content, a seamless finish, and strong anti-corrosive properties.Q: What safety and storage considerations should be followed for coal tar epoxy?

A: The coating material should be stored unopened in a cool, dry place to maintain its shelf life of 12 months. Post-curing, the toxicity is low, making it safe for use in most settings. During application, proper ventilation and safety measures are advised.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email